Buyer's Guide: The Original, Patented Yard Glider vs. The Imitations

The Correct Way

The Yard Glider® Solution: Integrated & Tear-Proof Design Our patented design completely re-engineers the pull point. We don't just bolt parts on; we use a proprietary process to heat, form, and cure the glider material around a galvanized steel bar. This creates a fully integrated, seamless pull point that evenly distributes force across the entire width. It's engineered for maximum strength, optimal pulling efficiency, and is simply impossible to tear out like conventional grommet-based systems. This is how a heavy-duty glider should be built.

Red Flag #2: Unrealistic Surface Claims

Honesty is crucial when it comes to a tool's durability. Be wary of brands claiming their basic 1/8" HDPE sleds can handle frequent, heavy use on abrasive surfaces like concrete, asphalt, or gravel. They often have to make these impossible promises because they don't offer stronger, specialized options.

The Truth About Materials: Our standard HDPE is incredibly tough and perfect for years of heavy use on lawns, dirt, snow, and other natural terrains. It can handle an occasional trip across a sidewalk. However, for anyone planning frequent use or heavy loads on abrasive surfaces like concrete, asphalt, or gravel, the laws of physics demand a tougher material. That's why we invested in offering specialized, abrasion-resistant UHMW in multiple thicknesses for our PRO and Extreme models—it's what it takes to build the right tool for the toughest jobs. We're here to give you honest guidance, not sell you a product that will wear out prematurely.

Red Flag #3: Deceptive "Easy Pull" Marketing

You'll often encounter marketing visuals showing someone effortlessly pulling thousands of pounds by hand with an imitation sled. Let's be realistic: while the Yard Glider® makes hauling significantly easier, pulling anything over 200 lbs manually requires substantial effort, especially on anything but perfectly smooth ground.

The Reality of Manual Hauling: Pulling by hand is best suited for maneuvering an empty glider, hauling very light loads like pruning debris, or covering short distances on perfectly smooth surfaces. Photos depicting individuals effortlessly dragging hundreds or even thousands of pounds by hand are simply misleading.

Our Commitment to Honesty: We show you realistic use cases. The Yard Glider's true power and incredible efficiency are unlocked when it's attached to your mower, ATV, or tractor, allowing you to move heavy loads that were previously impossible to manage by yourself. We believe in providing accurate expectations, not exaggerated claims.

Red Flag #4: "Assembly Required" Signals a Weaker Build

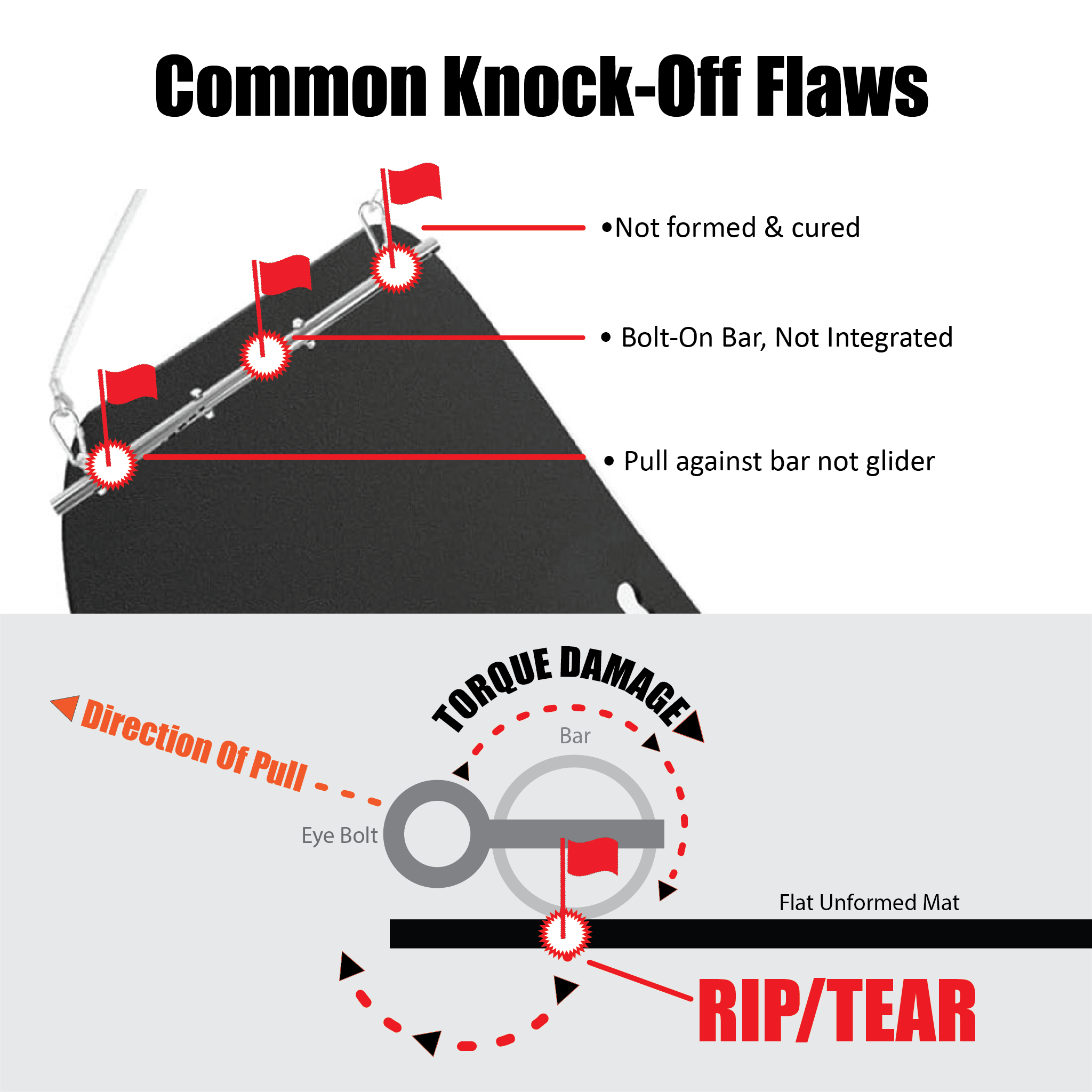

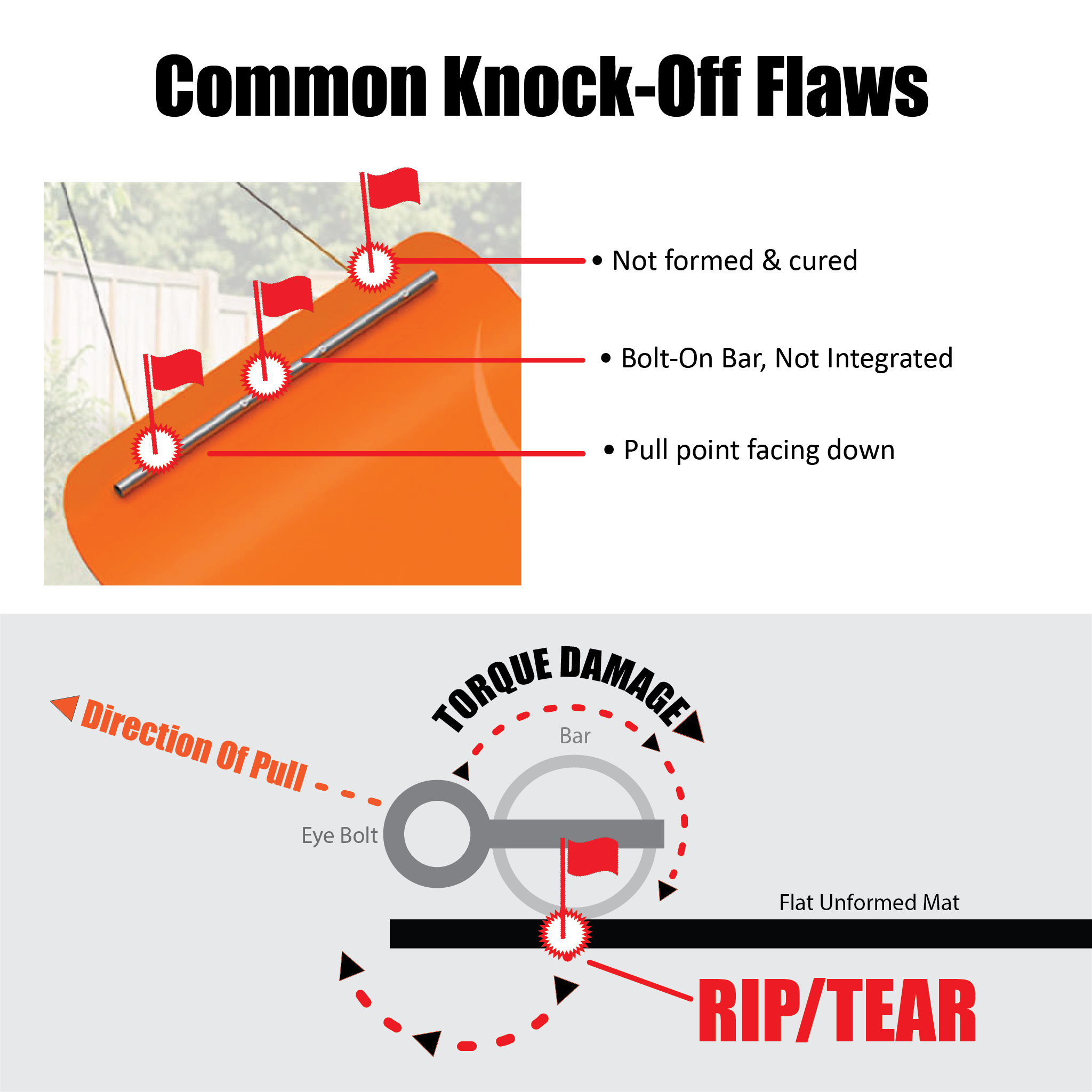

When you see "Assembly Required" for a drag sled, it's not just an inconvenience—it's often a direct indicator of a fundamentally weaker design. Why? Because a truly integrated, formed pull bar cannot be assembled by the customer; it must be built into the glider during manufacturing.

The Connection: "Assembly Required" usually means you're simply bolting parts onto a flat sheet, creating the exact weak points prone to tearing that we discussed in Red Flag #1.

The Yard Glider® arrives fully assembled and ready to work precisely because our patented pull point is integral to the structure. Skip the frustrating instructions and choose the confidence of an engineered, factory-built tool.